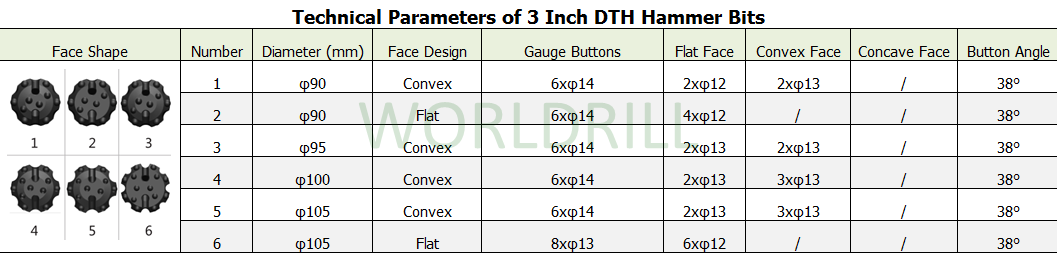

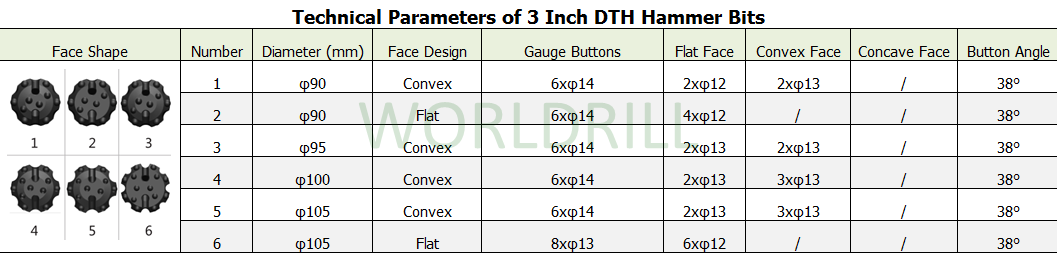

Designed exclusively for 3” DTH hammers, our DTH bits are engineered to deliver exceptional performance across 85mm to 105mm boreholes—aligning with the optimal drilling range of 3” DTH hammer systems like DHD3.5, COP35, TD35.2, QLX35, Terranox 3, COP32, COP34, and Mission30. Crafted for versatility, these bits excel in core industries where 3” DTH hammers are widely deployed, solving the critical need for reliable, wear-resistant drilling components.

These bits feature industry-standard spline drives and shank designs (compatible with DHD, QL, COP, and BR series 3” hammers) to ensure seamless pairing with most 3” DTH hammer models.

Optimized for the lightweight, flexible performance of 3” DTH hammers, these bits shine in:

Mining & Quarrying: Ideal for blast hole drilling in granite, limestone, and ore deposits—high impact frequency cuts through abrasive formations while minimizing wear, even in surface mining and bench drilling.

Water & Geothermal Drilling: Excels in medium-depth domestic/agricultural wells (up to 50m) and shallow geothermal projects, with efficient air flushing to clear debris in mixed rock conditions.

Civil & Exploration: Used for foundation anchoring, seismic drilling, and small-scale construction—compatible with portable crawler rigs for on-site mobility.

Performance Advantages

Durability: Premium alloy steel bodies and heat-treated tungsten carbide buttons extend service life by 20%+ compared to standard bits in abrasive formations.

Efficiency: Strategic button layout and airflow channels boost penetration rates while reducing air consumption—critical for 3” hammers’ medium-duty operation.

Versatility: Adaptable to soft, medium, and hard rock (6–8 Mohs hardness), eliminating the need for multiple bit types across projects.

Trusted by global drilling teams for mining, water well, and construction projects, our 3” DTH-compatible bits balance reliability and cost-effectiveness. Contact us for custom button/face designs or bulk ordering specifics.